-

Process

Oil RefineryPetrochemicalsNatural GasChemicalEnvironmental ProtectionGasFertilizerRenewable Energylron&steel

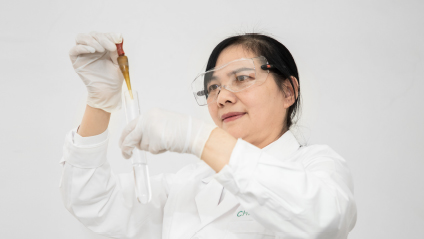

CHEMPACK provides essential chemicals and solutions for the oil Refinery industry,

supporting efficient fuelproduction and process optimization.Catalysts, Adsorbents Support BallsChempack is the approved OEM catalyst and adsorbent supplier

of Sinopec and PetroChina.CHEMPACK provides essential chemicals and solutions for the oil Refinery industry,

supporting efficient fuelproduction and process optimization.Catalysts, Adsorbents Support BallsChempack is the approved OEM catalyst and adsorbent supplier

of Sinopec and PetroChina.CHEMPACK provides essential chemicals and solutions for the oil Refinery industry,

supporting efficient fuelproduction and process optimization.Catalysts, Adsorbents Support BallsChempack is the approved OEM catalyst and adsorbent supplier

of Sinopec and PetroChina.CHEMPACK provides essential chemicals and solutions for the oil Refinery industry,

supporting efficient fuelproduction and process optimization.Catalysts, Adsorbents Support BallsChempack is the approved OEM catalyst and adsorbent supplier

of Sinopec and PetroChina.CHEMPACK provides essential chemicals and solutions for the oil Refinery industry,

supporting efficient fuelproduction and process optimization.Catalysts, Adsorbents Support BallsChempack is the approved OEM catalyst and adsorbent supplier

of Sinopec and PetroChina.CHEMPACK provides essential chemicals and solutions for the oil Refinery industry,

supporting efficient fuelproduction and process optimization.Catalysts, Adsorbents Support BallsChempack is the approved OEM catalyst and adsorbent supplier

of Sinopec and PetroChina.CHEMPACK provides essential chemicals and solutions for the oil Refinery industry,

supporting efficient fuelproduction and process optimization.Catalysts, Adsorbents Support BallsChempack is the approved OEM catalyst and adsorbent supplier

of Sinopec and PetroChina.CHEMPACK provides essential chemicals and solutions for the oil Refinery industry,

supporting efficient fuelproduction and process optimization.Catalysts, Adsorbents Support BallsChempack is the approved OEM catalyst and adsorbent supplier

of Sinopec and PetroChina.CHEMPACK provides essential chemicals and solutions for the oil Refinery industry,

supporting efficient fuelproduction and process optimization.Catalysts, Adsorbents Support BallsChempack is the approved OEM catalyst and adsorbent supplier

of Sinopec and PetroChina. - Products

- Services

- Sustainability

- About Us

- Blog

- Contact